SELECTION OF A RIGHT SEWING NEEDLE- 4 FREE HACKS AND TIPS

Selecting a right sewing needle can have a positive impact on the overall quality and ease of your sewing project. The right needle can make a huge difference in the way the fabric looks and feels, and can even help prevent damage to your machine. Choosing the correct sewing needle can greatly improve the overall quality and ease of your sewing project.

What is a needle?

Every component of a sewing machine plays a pivotal role in its functioning so is the needle . A needle is a long slender piece of metal that contains a small hole at is end to add thread and helps to sew.

What is the function of a needle?

1. The needle is basically used to sew variety of fabrics by using the thread that is added to it.

2.The needle passes the thread onwards through the material by the looper mechanism forming a loop.

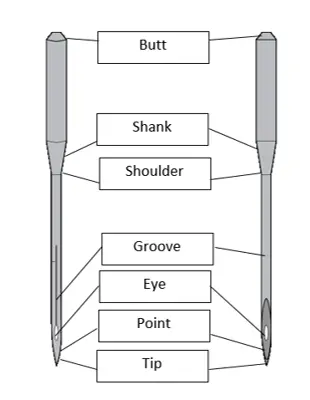

What are the parts of a needle?

What are the functions of different parts of a needle?

- Tip: Tip is the most extreme end of the sewing needle that enters the fabric first.

- Point: Just behind the tip is the point. The needle is selected based upon mainly the nature of the point. The pointed needle or blunt needle both have different properties and both are used for different types of fabrics.

- Eye: The “eye” of a needle is a small hole or opening at the end of the needle where the thread is passed. The eye of the needle is usually located at the end of the needle, near the pointed end, and is specially designed to allow the thread to easily pass through and form stitches in the fabric.

- Groove: The groove is the space that is present onside the needle with variable length and width depending on needle type, and helps in formation of loop of thread.

- Shoulder: The slanting space just below the shank is the shoulder.

- Shank: In between the shoulder and butt of needle, shank is located. It is the portion that is the support of the needle. It may be cylindrical shape at one side and flat on the other side. It is the portion of the needle that is inserted into the needle clamp of the sewing machine and is held in place by a knob.

- Butt: On the top of needle is the needle butt or the needle head. It is the main portion of the needle that is added to the needle bar of the sewing machine.

4 Reasons to choose the right sewing needle

Dependent on fabric

Different types of needles are needed for various fabrics, such as a sharp needle for knit fabrics or a ballpoint needle for woven fabrics. The cloth won’t be harmed when sewing if the proper needle is used, and the stitches will look their best.

Stitch property

Using the right sewing needle can impact the appearance and tensile strength of the stitches. For instance, a sharp needle produces neater, more accurate stitches, and a ballpoint needle helps knit fabrics avoid laddering

Compatibility with sewing machines

Some sewing machines need particular kinds of needles so read the user manual to confirm which type of needle your sewing machine is using. It is possible to avoid machine damage, maintain accurate needle alignment, and get the required results by using the right needle.

Compatibility with the chosen thread

The needle’s eye should be of the appropriate size for the thread thickness. The thread may be kept from breaking or fraying by using the right needle, which also ensures that the needle and thread work effectively together to produce even, smooth stitches.

Therefore, using the right sewing needle in a sewing machine is crucial for producing the greatest results, guarding the fabric and the machine, and providing a quick and easy stitching process.

Different types of needle and their characteristics

Leather needle

| Needle size | 80/12 –110/18 |

Characteristics of leather needle

Overlock needle

| Needle size | DCX1: 2-11& 3-14; BLX1: 2-11& 2-14 |

Characteristics of overlock needle

Ball point needle

| Needle Size | 70/10 –100/16 |

Characteristics of ball point needle

Sharp needle

| Needle size | 60/8 –120/19 |

Characteristics of sharp needle

Denim sewing needle

| Needle size | 70/10 –110/18 |

Characteristics of denim sewing needle

Selection of a right needle size depending on fabric – Needle size chart

| Fabric | Needle Size |

| Lighter fabric | 65/9 – 75/11 |

| Medium Fabric | 75/11 – 90/14 |

| Stretched Fabrics (knit) | 75/11 – 90/14 |

| Heavy Fabric | 80/12 – 110/18 (Leather) |

Read More: Different types of needles to sew leather

Conclusion – choosing a right sewing needle

In conclusion, choosing the right sewing needle is important to ensure a successful sewing project. Factors to consider include the type of fabric, the type of project, and the size of the thread. By taking these factors into account, you can select a needle that will provide the right combination of strength, sharpness, and smoothness to achieve the desired results.

Perfect Sewing Machine Needle For Different Types Of Fabrics