SEWING MACHINE TENSION GUIDE: 4 QUICK HACKS

Sewing is an art that requires accuracy and precision in detail. The most important factor that can affect the quality of your sewing machine tension, and sewing machine thread tension guide can be very much useful for this purpose. In this tutorial, we will provide you with detailed guidance on setting and adjusting the thread tension on your sewing machine.

Sewing machine tension is quite a delicate issue that requires symmetry to achieve flawless stitches. If you are facing thread tension problems, then you should understand the sewing machine tension guide.

Sewing machine tension guide: Uses

- Pursuing the sewing machine tension guide can result in perfect stitches, no thread breakage, and even no damage to the machine.

- The sewing machine tension guide will provide the right directions on setting the thread tension, which can be varied depending on the fabric and thread quality as well as, stitch type.

- The sewing machine tension guide will help you to adjust the thread tension and resolve various issues.

When the top thread is too loose or the bottom thread is too tight, then slightly increase the upper thread tension. And if otherwise, that is the bottom thread is too loose or the top thread is too tight, then decrease the upper thread tension. If the bobbin thread is too loose then adjust the bobbin tension screw to increase the tension. It’s essential to make small adjustments and test your stitches on a scrap piece of fabric to achieve perfect tension.

Sewing machine tension setting

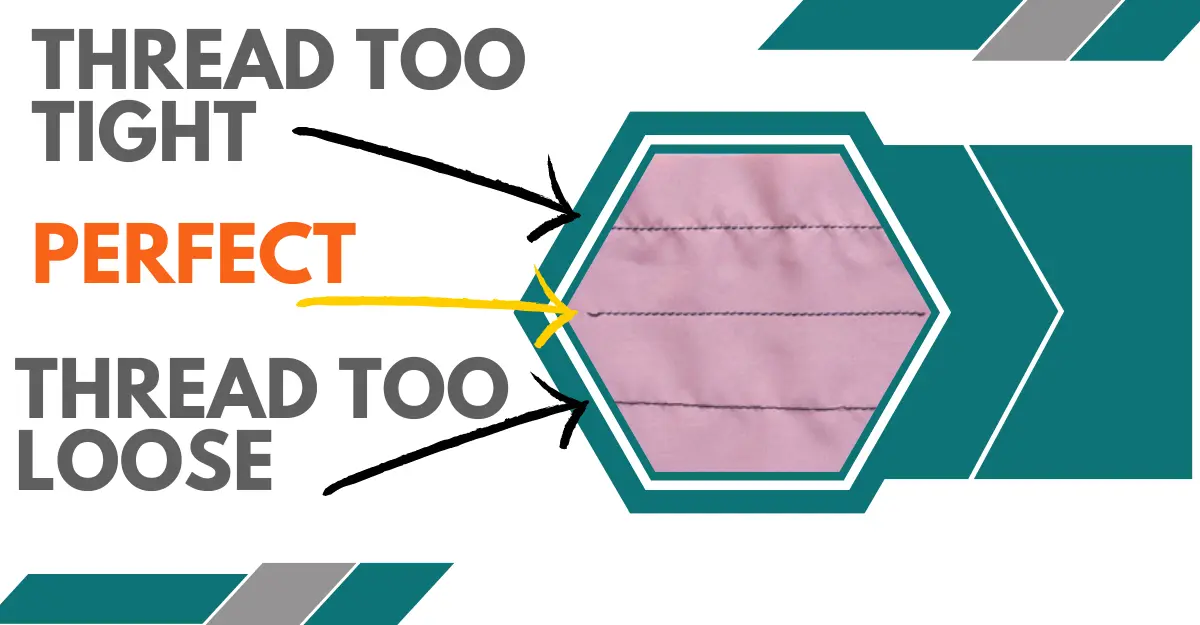

The most common issue faced by a sewer is inaccurate sewing machine tension setting. When the tension is too tight, the thread will break, and if it is too loose, the thread may bunch up under the fabric or create loops on it. This will result in low-quality stitching which could be frustrating and time-wasting.

Adjustment of tension setting in sewing machine

The solution to this problem is, first of all, to check and adjust the sewing machine tension setting. Make sure that the machine is threaded correctly and according to the given manufacturer’s instructions. When it is done, take a scrap piece of fabric and make a test stitch on it with the same thread and fabric you want to use for your project. Inspect the stitch to find any tension issues.

If the stitch is too tight then lose the tension setting by adjusting the tension dial to a lower number. If the stitch is too loose, tighten the tension by adjusting the dial to a higher number. Keep adjusting until you get the desired stitch quality. Remember to sew on scrap fabric until you achieve the perfect tension.

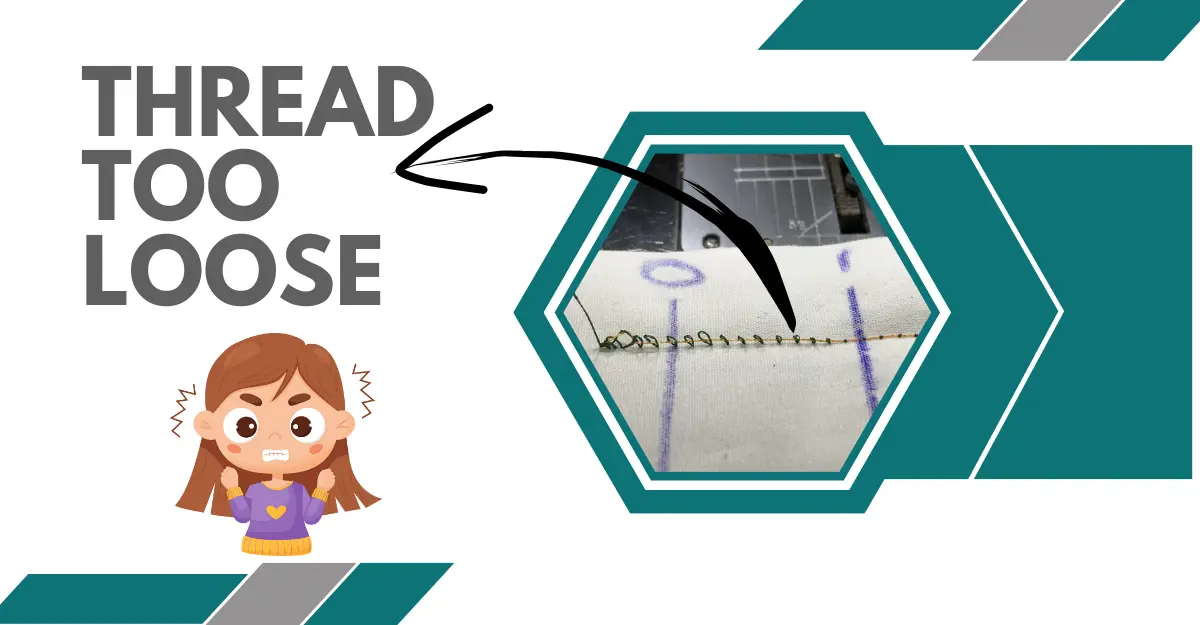

Thread loose

Loose thread on a sewing machine is irritating and leads to a number of sewing problems. It may cause uneven stitches or multiple thread breakage. Loose thread on a sewing machine may be due to several reasons, which include incorrect tension settings, irrelevant threading, a dirty machine, or a worn-out needle.

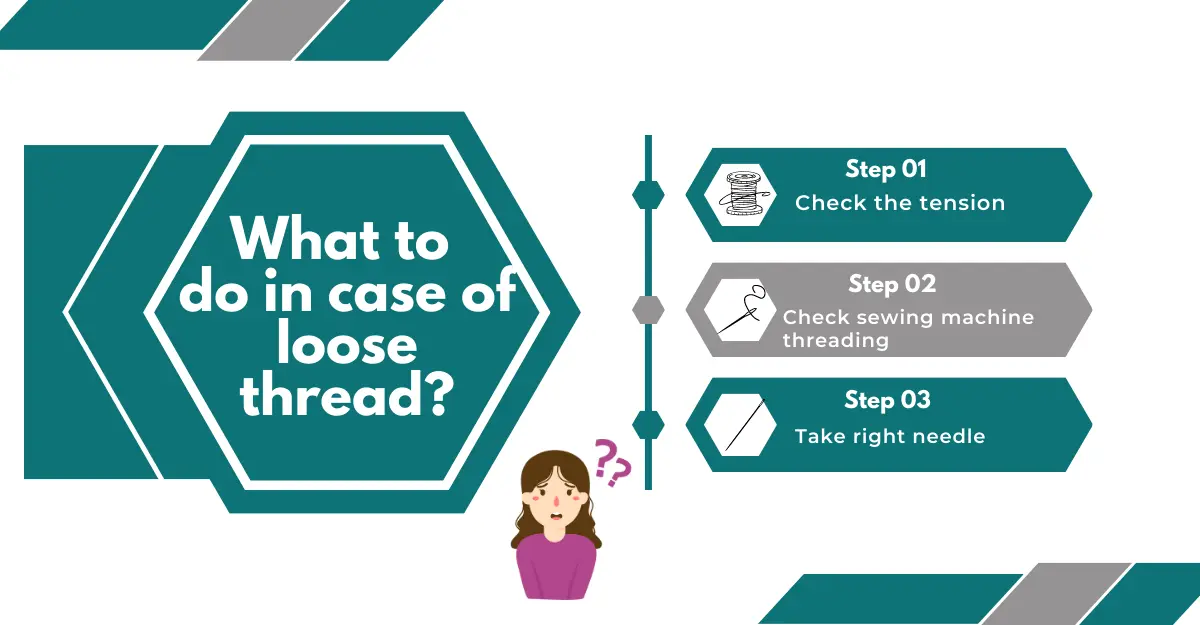

First of all, check these factors and make the necessary corrective measures. Make sure that the tension is not too loose, and that the thread is appropriately threaded through the machine.

In case the tension is right, but the thread is still loose, it may be due to the wrong-sized needle for the fabric and thread. Check that the needle is the right size and it is inserted in the right direction. A dull needle can also cause loose thread, so replace the needle if it is worn out.

Another common cause of loose thread may be a worn-out bobbin case or improper bobbin winding. Make sure that the bobbin is wound correctly and that the bobbin case is not damaged. If the bobbin case is damaged, it may need to be replaced.

Tension adjustment on sewing machine

Sewing machine tension problems can lead to a lot of frustration when the stitches are not looking neat and professional, therefore in order to avoid the trouble just relax and calm down. You need to fix the thread tension.

The primary reason of thread tension problems is incorrect tension adjustments on the sewing machine but if tension is adjusted properly this problem can be resolved. If the tension is too tight or too loose, it can cause a variety of issues such as thread breakage, loops, and seam puckering; therefore thread tension is adjusted to overcome these problems. To every problem in this world there is a solution. From this sewing machine tension guide, it is obvious that you have to adjust the tension to avoid the problems of tension.

To solve sewing machine tension problems, it’s crucial to understand how to adjust the tension on your machine by consulting the thread tension guide. To adjust the tension, locate the thread tension dial on your machine. If the thread tension is too tight, turn the dial to a lower number. If the tension is too loose, turn the dial to a higher number. This will help you identify any tension problems early on and make the necessary adjustments before working on the actual project.

Tension on sewing machine

Sewing machine thread tension problems can be irritating because if the tension is too tight or too loose, it may cause uneven stitches, thread breakage, or fabric puckering.

To solve tension problems on your sewing machine, you need to understand how to adjust the tension correctly.

Step 1: Check your needle

To start with check that the machine is threaded correctly, and the needle is in the right direction as well as right-sized for the thread and fabric being used.

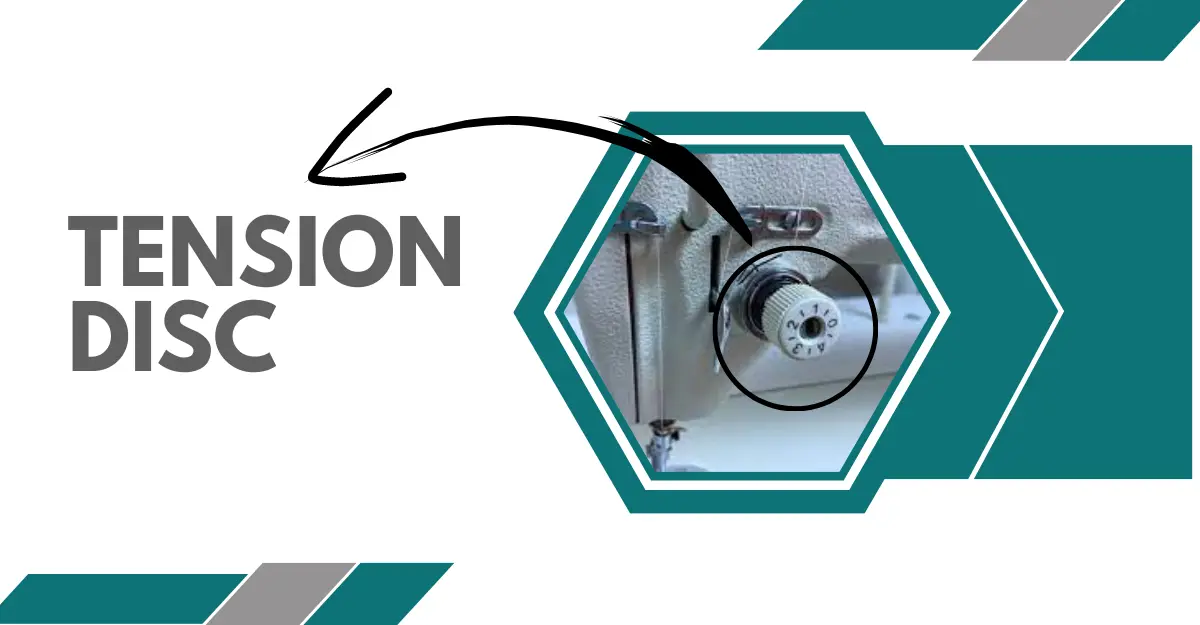

Step 2: Locate the tension disc on sewing machine

Next is to locate the thread tension dial on your machine. The thread tension dial is an important tool for adjusting the tension on your sewing machine.

Step 3: Rotate the dial to adjust tension

By turning the dial, you can increase or decrease the tension of the thread as needed. If the tension is too tight, turn the dial to a lower number. If the tension is too loose, turn the dial to a higher number. Keep testing and adjusting the tension until you achieve the desired quality stitch work.

Different fabrics have different tension settings

An important point to note is that different fabrics and threads may require different tension settings. For example, lightweight fabrics may require lower tension than heavier fabrics. In case of any doubt, refer to your machine manual or consult with the specialist.

Maintenance of accurate tension

Maintenance of accurate tension on your sewing machine is very important for achieving high-quality sewing. It is, therefore, very important to check the tension periodically, especially when switching between various fabrics and threads.

Read more: Best Sewing Machine For Home Use

Conclusion

In conclusion, perfecting sewing machine tension adjustment is the secret to effortlessly producing beautiful and expert-looking stitches. You can put an end to aggravation and have a seamless sewing experience by comprehending the typical causes of tension issues and putting the suitable solutions into practice. You can produce immaculate stitches that will have you and everyone else in awe of your sewing prowess with the correct materials, techniques, and optimistic mindset. So go ahead and let your sewing machine work its magic while you let your creativity run wild!

How to Adjust Tension on Sewing Machine: Sewing machine tension guide