10 MAJOR SEWING PROBLEMS, ISSUES AND INCREDIBLE SOLUTIONS

Whenever you are using a sewing machine regularly, it is obvious that as a routine user you may face some sewing problems or issues; but whenever any problem in sewing arises just relax, because to every problem there is always a solution. So, in this article we will take a look at some common sewing machine troubleshooting and will also discuss easy solutions to these problems.

Common Sewing problems

Breaking of needle thread

Out of many sewing problems one that may arise in sewing is breaking of threads in needle but keep calm when you face this sewing problem. The user should focus on the basic key points that could be helpful to avoid breakage of threads. If a thread is breaking when sewing, it may be a sign that the sewing machine like singer 4411 is working well and that the thread being used needs to be replaced. You should select the right thread for sewing in order to avoid this problem.

This will be helpful to avoid more problems and will extend the machine’s lifespan. Additionally, the user’s technique might lead to thread breakage but don’t worry. By correcting this with the right learning and practice, stitching will become more effective and efficient. In general, when sewing leather, thread breakage in sewing machines can act as a warning indication and encourage better machine maintenance and sewing proficiency.

The user must recheck the thread that whether there is any knot in the way anywhere around the needle or not and if there is a knot fount then remove the knot first so that the issue may be resolved.

Also if the thread the user is using is made up of natural fiber the thread may be old enough to keep its seam strong therefore it would be breaking, but don not worry at all; all you have to do is to replace the old thread with the new one. It is possible that tension has been kept too tight for the thread that causes it to break but it can be avoided by keeping the tension low so that the thread do not breaks when sewing.

Needle breakage

During sewing especially in sewing denim or other heavy duty fabrics, the needle breaks suddenly and causes problem, but do not worry because it indicates the user that the machine is functioning properly but you have to note down the causes.

Usually needle breaks if the tension in bobbin case is increased to a high extent but this problem can be resolved by decreasing the tension in bobbin case. If you are using wrong type of presser foot then your needle may break so be careful while sewing and choose the correct needle!

If your needle has broken while sewing replace it with a new one. This can prevent further issues from occurring and will increase the lifespan of the machine. Another important point is that you must select the correct type of needle especially when sew in wigs for your sewing machine.

There are many types of needles with variable thickness that are used differently in different types of machines to sew variety of fabrics. You should choose the needle type wisely according to your requirement. The size of the needle that you are using also matters while sewing. It must be noted that the light weight fabric require needles with pointed and thin edges while heavy duty fabrics would require thicker edged needles.

Sewing machine stitch problems

Whenever you face stitching problems with your sewing machine there may be some issues like sewing machine not stitching, problem sewing machine stitches, and why is my sewing machine not sewing. These issues may be caused by incorrect thread tension, damaged needles, or the wrong type of thread or fabric. In order to troubleshoot these issues, consult your machine’s manual for guidance on sewing machine troubleshooting. Adjust the thread tension and needle insertion. Always keep in mind that stitching problems on sewing machine or problem with sewing machine stitches may not prevent you from completing your project.

There are several reasons why your machine may not be stitching properly. One common problem may be that the thread tension is incorrect, which can cause the thread to break or bunch up. Other possibility may be that the needle is damaged or incorrectly inserted. Moreover, using the wrong type of thread or fabric can also cause sewing problems. To troubleshoot these issues, check your machine’s manual for guidance on adjusting thread tension and needle insertion. You may switch over to a various types of thread or fabric to see the improvement in stitching. By addressing these problems, you can ensure that your sewing machine is functioning properly in all respect.

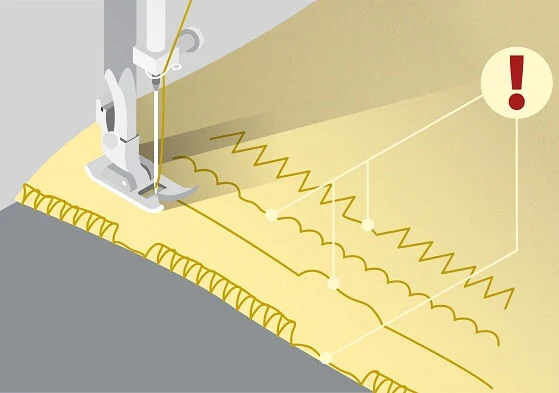

Stitched line gathering a wrinkling look

This is normally referred as SEAM PUCKERING. A seam pucker occurs when thread tension is kept high so the thread tension must be low to avoid. Seam puckering can also be a sign that the sewing machine tension needs to be adjusted. This can help the user to understand how to adjust the machine tension and how it affects the sewing results. When the fabric is stretched more but less thread comes in its way then the fabric can get a wrinkling look, so to avoid this, the fabric should not be stretched more while sewing.

Read more: Measuring tools in sewing

Uncut thread ends

Lose or uncut thread ends are the sewing problems that arise while sewing and they can easily be avoided. This means the loose ends of the thread should not be left behind after the work has completed. Incorrect threading also may be the cause, but mostly this is in the hand of workers. An uncut thread end can be a sewing problem for certain types of sewing, such as when creating gathers or ruffles, as it allows for the thread to be pulled through the fabric more easily.

Seam failure

In a sewing machine, seam failure can be observed as a positive point of view because it allows the user for the identification and correction of mistakes in sewing. If a seam failure occurs, it is a sign that the sewing machine needs to be threaded. It may also indicate that fabric is not put in the sewing machine properly, also the needle or thread could be changed according to the fabric type.

Additionally, seam failure can also be a chance for investigation and creativity of art and design. Additionally, it also can be used as a golden chance to improve the user’s sewing skills and awareness of the machine’s proficiencies. It may also help the user to get more familiar with stitching and sewing problems and be more confident with the machine.

Stitches that are skipped (jumping stitches)

In a sewing machine when the stitches are jumped it is an indication that the machine is not operated at the correct tension level. Therefore, by the adjustment of thread tension, the stitch appearance would be improved. By testing with different threads, needles, and adjustment of different thread tensions the user can quickly identify the problem in jumped stitches.

Fusion of thread (Nest forming stitches)

Thread fusion (bunching of thread) is the sewing problem that would arise if the threading of sewing machine has not been done properly. If the thread is not properly passed through the needle guide it will cause the thread to fuse and form a nest or knots. By keeping it sure that the machine is properly threaded the art of sewing can be made smooth, efficient and easy. Bunching of thread can be taken as a chance of learning for the beginner in sewing. Identification of the correct cause of the problem and finding its solution is the only way one can avoid thread fusion.

Variable stitch length

Many sewing problems have been discussed above but stitch length issues may also arise in modern day sewing machines where you have to adjust it according to the type of stitch you are using or also depending on the type of fabric that is being used. With variable stitch length, the user can adjust the length of the stitches to suit the project and the fabric being used.

Manual guide should be consulted if there is some problem regarding variable stitch length. If the requirement of your fabric is a large stitch but your sewing machines makes a short stitch, consult the user guide to adjust the stitch length according to your sewing machine. These sewing problems also arise when you are sewing a t-shirt with a sewing machine.

Lose stitch below the fabric

A loose stitch below the fabric occurs when the machine is set to a lower tension level, which causes the thread to appear loose and saggy on the underside of the fabric. This is typically done when working with delicate or lightweight fabrics to prevent the fabric from puckering or pulling too tight.

Thread tension below the fabric matters a lot in that case. The tension in bobbin is a major factor that has to be noted. It may also help the user to get more familiar with stitching and sewing problems and be more confident with the sewing machine. By identifying and adjusting the tension level, the user can improve the quality of their sewing and prevent future loose thread issues.

Read more: Why you need a sewing machine

Conclusion – Final words

As a whole, in my opinion any sewing machine that is being used regularly can cause some troubleshooting but just by simple hacks and tricks, sewing machine problems can be avoided and in this way, the quality of sewing can be improved for the better.

Explore more: Best Brother sewing machines