SEWING MACHINE BOBBINS-(5 EXPERT TIPS)

Whether you sew on a manual sewing machine or an automatic sewing machine, you have to keep in mind how to identify the right sewing machine bobbins.

Apart from choosing the right thread and right needle, selection of an ideal sewing machine bobbin for your machine is an important step while sewing, because bobbin is helpful in maintaining the stitch tension, also the right bobbin helps your sewing process to be smooth and effective. It is the correct bobbin that would help your sewing thread o intermingle and make effective stitch from top and bottom. The machine might not stitch correctly in the absence of a properly turned bobbin, frustrating the user and possibly ruining the project. Therefore, take the time to check the bobbin and make sure that it is wound properly and put in the machine before attempting to sew, like sewing on the snap button. This will help produce a final product that is more polished while also facilitating a smoother process. Therefore selection of the right sewing machine bobbin is very much needed.

What is a Sewing Machine Bobbin?

Bobbin is the cylindrical shaped part of the sewing machine on which thread is wound and it is inserted in the sewing machine and helps the sewing machine by providing the bottom thread. It is one of the tiny little parts of the sewing machine, that may not be looking so much effective but actually they play very important role in sewing machine. It helps the upper thread by making stitches on the bottom side of the fabric. It also assists to hold Seams together. Front Load Bobbins need a bobbin case where as the Top Load Bobbins don’t. In proper working of your bobbin will make you unable to Sew.

Working of a sewing machine bobbin?

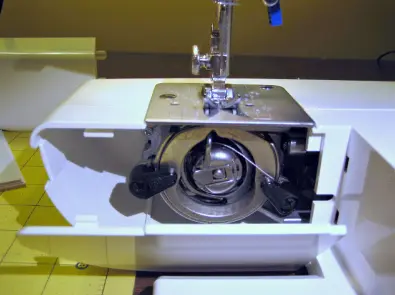

Front Load Bobbin:

The Bobbin fits into a metal case and snaps into the front of a machine is known as Front Load Bobbin. The thread pulled out from the bobbin feeds through the bobbin case before being “picked up” by the needle. Once everything is in place, close the cover.

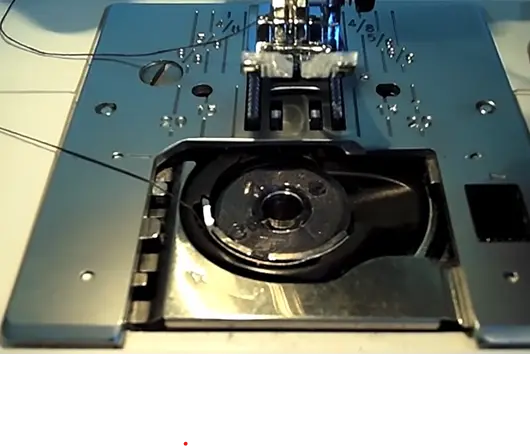

Top Load Bobbin:

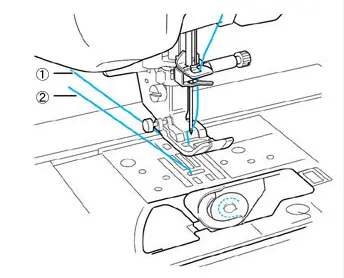

The Bobbin dropped in by removing the plate along the presser foot is known as Top Load Bobbin. The thread is then pulled through the bobbin mechanism to get picked up by the needle. Once everything is placed, snap the cover back on. Check the manual for directions that your thread is working properly.

How does the bobbin thread work in a Sewing Machine?

Sewing machine bobbins as well as thread bobbins are pivotal components of a sewing machine. The Lockstitch requires two threads that is i.e., an upper thread and a lower thread. The upper thread feeds from a spool and is threaded through the needle. The lower thread feeds from the bobbin which provides a loop for the upper thread to catch onto, completing the stitch. The stitch could be uneven or weaken over time if the bobbin thread isn’t operating correctly. Make sure the bobbin thread is wound accurately and threaded through the machine before beginning to sew on the 4-hole button. This will make it easier to guarantee a solid, even seam and a firmly fastened button.

What are the different types of bobbin?

| Types | Diameter | Height |

| L-style | 2.03 cm | 0.89 cm |

| M-style | 2.49 cm | 0.67 cm |

| Class-15 | 2.03 cm | 1.17 cm |

L-style Bobbins

M-style Bobbins

Class-15 Bobbins

How to identify right bobbin for a sewing machine?

Check the user manual

Whenever the thought of How to identify the right bobbin for a sewing machine enters our thoughts for your sewing machine, you must use the user manual that is came up with the sewing machine in section: parts.

Compatibility of bobbin with sewing machine

First of all check whether the bobbin that you are using is compatible with your sewing machine or not because the compatibility of bobbin is very much important. Remember that every bobbin is not same, means that they are of different types and choosing the wrong bobbin can harm your sewing machine.

Size of the sewing machine bobbin

Check the size of the bobbin that actually came up with the machine for selecting the right size bobbin. Remember that if your machine uses a standard size bobbin then it is not a problem, but if your machine uses a different one then try to find the correct replacement.

Material of the bobbin

Remember that bobbins may come in plastic or metal. The plastic bobbins are less expensive and affordable but they have a limited warranty.

Style of the bobbin

Bobbins may look the same but in a closer look they may not be exactly the same because they come in different shapes and styles. So be careful while selection. The bobbins used for an industrial sewing machine are usually larger as compared to domestic sewing machines.

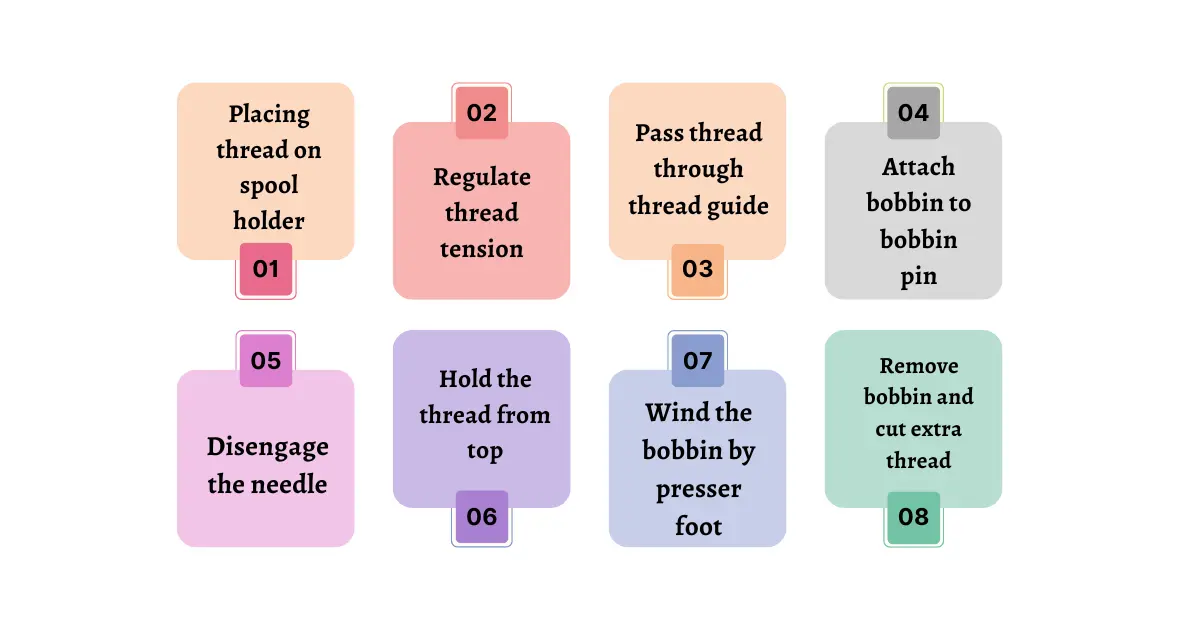

How to wind a bobbin?-8 Easy Steps

1. Placing thread on thread holder

Place thread spool on thread holder of your sewing machine.

2. Maintenance of thread tension

Regulate and maintain thread tension while winding a bobbin.

3. Passing thread through thread guide

Pass the thread through the tiny hole also called as thread guide so that your thread does not lose its place. Take a closer look at the bobbin, you will see a small hole in it and now pass the thread through this hole and pull this thread now and hold it up.

4. Attachment of bobbin to winding pin

Now attach the bobbin to the bobbin winding pin and lock it in that place.

5. Dis-engage the Needle

In the next step you have to stop the needle from moving. For this purpose on the right hand side of the machine push the bobbin winder pin.

6. Hold thread from top

Hold the thread from the top so that it does not get intertwined.

7. Wind the bobbin by presser foot

Now place the pressure on the pedal or presser foot and allow to wind the bobbin though the number of times and then use a scissor to cut the thread.

8. Remove bobbin from pin and cut extra thread

The bobbin in wound now. Now you can remove it from the pin and cut the extra thread from the hole of bobbin.

7-Things you must know about Sewing machine Bobbins

- How many bobbins do you really need?

- What bobbin size do you need?

- Use the right bobbins that are made for your machine

- Difference between plastic bobbins and metal bobbins

- Difference between universal and interchangeable bobbins

- Insertion of bobbin in right directions

- Do not mix different size bobbins in sewing kit

Conclusion-How to identify the right sewing bobbin

Identification of the right bobbin for your sewing machine is essential to ensuring successful and efficient sewing. Consider compatibility, size, material, style, and thread type when choosing a right bobbin. By doing so, you’ll be well on your way to creating beautiful and professional-looking projects.