HOW TO THREAD SEWING MACHINE-(10 EASY STEPS)

Before you start sewing, the first question that pops up in your mind is how to thread sewing machine? Threading a sewing machine needle is a skill that requires patience and precision. It’s a great way to improve your hand-eye coordination and fine motor skills.

Once you understand threading of a machine, you’ll discover that it becomes second nature and gets easier every time. Eye magnifying lenses can be used in threading a needle in case of poor eyesight.

The satisfaction of successfully threading a needle and creating a beautiful piece of embroidery, sewing, or other needlework is truly rewarding. Additionally, it can be a meditative and calming task that allows you to focus and unwind. Overall, threading a needle can be made enjoyable and expertise with practice because “practice makes man perfect”.

Pre-start up preparations for threading a sewing machine

If you have a sewing handbook, start by reading it. Diagrams directions are always provided in the user guide of the particular sewing machine.

Fill the bobbin with the color of thread you intend to use. Your chosen fabrics should work well with the thread you use. Following are the steps describing how to thread a sewing machine needle step by step.

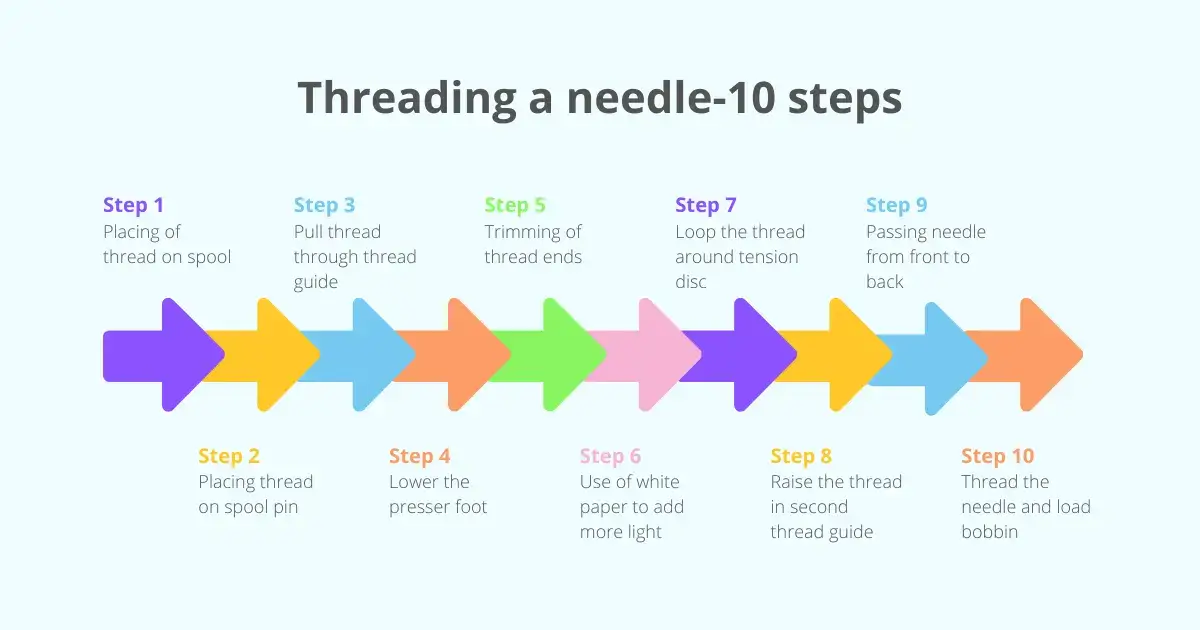

How to thread sewing machine (10 steps)

A sewing machine is threaded by moving the upper thread from spools pin across the top of the device, via the tension discs and uptake hook, then finally to the needle.

The winded bobbin is entered in the bobbin cases. Although each brand of sewing machine has subtle variations, the fundamental idea of where to place the upper and lower threads is constant.

1. Placing the thread on spool

Place the thread just on spool at the machine’s top. Depending on the model of your machine, this can be an upright or a lying-down nail or spool. To keep the spool in place and prevent it from flying off the top once you begin sewing, your machine could have a plastic disc that you can place on top of it.

2. Placing thread on spool pin

Put your thread spool on the spool pin. The hollow centre of thread spools makes it simple for the pin to access them. To reveal the thread spool’s core, first remove any stickers covering its ends.

3. Pulling of thread through thread guide

Through the thread guide at the top, now pull the thread. Usually, this will be a knob.

4. Lower the presser foot

You’ll have more room to manoeuvre around the needle if you lower the presser foot (manually, of course) or remove it entirely. In order to prevent the thread from pulling easily in your hands, lowering the presser foot bar will also engage the tension discs.

5. Trimming of thread ends

Make certain to use sharp scissors to trim the thread’s end to make the ends of thread clean and neat. It is also helpful by licking the thread. As closely as you can, hold the thread at the very end.

6. Use of white paper

To get more light and prevent shadows, use a tiny piece of white paper or a headlamp. Also, while the needle is not in the machine, it can be handy to detach it and thread it. The process of removing the needle and re-threading it is actually fairly simple.

7. Loop the thread around tension disc

The thread should be pulled downwards and then towards you to make the thread loop in tension disc.

8. Raise the thread through second thread guide

The thread is then passed in the second thread guide that is present. This will have a take-up lever, which is a lever with an eyelet. The thread forms a U as a result.

9. Pass thread from front to back

Then pass the thread through needle through from front to backward.

10. Thread needle and load bobbin

According to your wound bobbin’s kind and the manual’s directions, load it. The bobbin may be placed into your machine from the front or the top. Some machine models include a case that can be removed into which the bobbin can be inserted, while others just lower themselves into a fixed position.

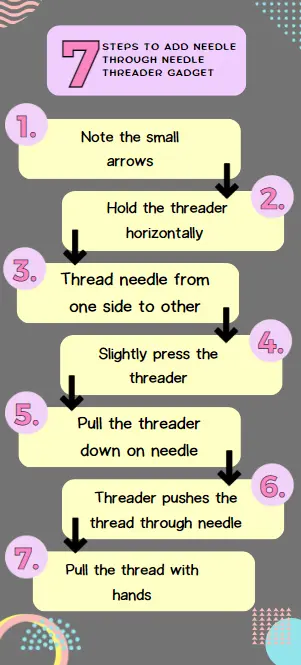

How to thread sewing machine needle easily through needle threader gadget (step by step)

1. Note the small arrows

The needle threader gadget has two signs of small arrows on it.

2. Hold the threader horizontally

So, with either arrow facing up, hold the threader horizontally.

3. Thread needle from one side to other

Thread the needle from one side to the other.

4. Slightly press the threader

Now, press slightly the threader throughout the needle, remembering not to hold it with your fingers.

5. Pull the threader down on needle

Pull the threader down on the needle until you hear or feel a click.

6. Threader pushes the thread through needle

As you push the threader, the small metal tong will push the thread through the eye of the needle.

7. Pull the thread with hands

You’ll notice a loop has been formed behind the needle eye. Pull the remaining thread in with your hand or tweezers.

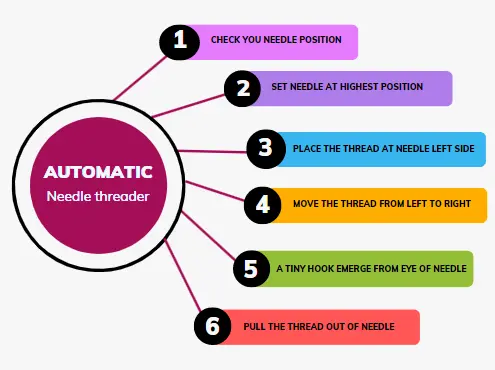

Adding thread through automatic threading sewing machine

A built-in automatic needle threader, which is readily accessible on many semi to greater rates of machines, also known as self threading sewing machine, is extremely useful.

The automatic needle threader feature can vary from a pull-down lever which you regulate to a push-button component that does all of the job for oneself.

Adding thread through automatic needle threader (Basic Steps)

1. Check your needle position

At order for the threader to align with the needle eye, first check that your needle is in its highest position.

2. Set the needle at highest position

If your machine has one, you can manually operate the hand wheel or you can press the needle up or down button.

3. Place the thread at needle’s left side

Keep the thread in place to the needle’s left.

4. Move the thread from left to right

Now, with some strain, move the thread from left to right in front of the needle and draw it down around the threader guide.

5. A tiny hook emerge from eye of needle

The needle’s eye will reveal a tiny hook that will emerge from the back toward the front.

6. Pull the thread out of needle

You can now take the thread out of the eye of the needle.

How to setup a sewing machine

Setting up a sewing machine is very simple which requires a little bit of patience and practice.

Putting a needle in a sewing machine

The question how to put a needle in a sewing machine like Singer 4411 is very simple. First of all make it sure that machine is unplugged. Then, locate the needle clamp and insert the needle into it. Tighten the clamp with the screwdriver for security reason.

Finally, turn on the machine and test the needle by stitching on a piece of fabric. If the needle is not centered adjust it necessarily.

Placing of spool thread

Firstly, take the machine out of the box and place it on a table. Next, turn it on by plugging into the switch. Now trace the spool holder and place the spool of thread into it.

Threading of bobbin

Then, bring the thread through the thread guide and wind it around the bobbin winder tension disc. Put an empty bobbin onto the bobbin winder spindle and start the machine. Once the bobbin is full, remove the bobbin and trim the thread.

Threading a sewing machine

After winding the bobbin, the next step for how to setup sewing machine is to thread the machine. Take the spool of thread and place it through the thread guide.

Threading of needle

Next, bring the thread up through the take-up lever, and then down through the needle guide. Thread the needle from front to back, and then pull the thread out.

Hold onto the thread and turn the handwheel to bring the needle down and back up again. This will catch the bobbin thread and bring it up through the needle plate. Finally, pull both threads to the back of the machine and you’re ready to start sewing.

Conclusion

Adding a thread through the above mentioned steps is much easy than any other way. You might also use a gadget to add needle to a thread or you are lucky enough to have a built in threader. Take a look at the below mentioned video link to get more instructions.

An Easy way to thread a sewing machine needle