How To Oil A Sewing Machine – Easy Guide

To sew patches on leather, first choose a strong thread like bonded nylon or polyester and use either a leather sewing machine or hand-sewing tools such as a curved needle and stitching awl. Clean the leather surface and position the patch using double-sided tape avoid pins to prevent permanent holes. If using a machine, select a leather needle and adjust the presser foot pressure to handle the thickness. Sew slowly along the patch edge with a straight or zigzag stitch. For hand sewing, use a saddle or whip stitch for a strong hold. Always test your method on scrap leather first to avoid damaging your final piece.

When you own a sewing machine, it is important for you to know “How to oil a sewing machine”. Anyone who enjoys sewing, quilting, or crafts will find a sewing machine to be a useful instrument. To make sure that your sewing machine performs smoothly and lasts for a long time, adequate maintenance is imperative.

Greasing a sewing machine is an important part of sewing machine maintenance. We’ll walk you through the procedure for how to oil sewing machine in this article. With our advice, you can effortlessly maintain your sewing machine and take pleasure in effortless, smooth sewing.

Why to oil a sewing machine?

Prior to learning how to oil a sewing machine, it’s critical to comprehend why lubricating sewing machine is required. Many moving components make up a sewing machine, and for these components to work properly, lubrication and proper oiling is necessary. A sewing machine’s moving parts might grow stiff or even start to grind against one another if it isn’t routinely maintained, which can harm the machine. Also, lubricating your equipment can aid in preventing corrosion and rust, both of which can impair its efficiency.

How often should you Oil a Sewing Machine?

It’s crucial to understand when to grease and oil your sewing machine. You risk harming your machine if you oil it too frequently. On the other side, if you don’t oil the machine sufficiently, it can not operate correctly. So how often should you oil a sewing machine?

Typically, your sewing machine should be oiled after eight hours of use. However, this can change based on the machine’s type and frequency of use. To find out how frequently to oil your sewing machine, consult the manual.

How to Oil a Sewing Machine: Step-by-Step Guide

Now that you understand the importance of oiling your sewing machine and when to do it, it’s time to learn how to oil a sewing machine. Follow these simple steps to keep your machine running smoothly and get it maintained.

Step 1: Collect Ingredients

Make sure you have everything you need before starting. You will require cotton swabs or a soft cloth or a soft brush, sewing machine oil, and a screwdriver (if needed).

Step 2: Switch off the sewing machine

Make sure your sewing machine is unplugged and switched off before you begin lubricating it. This is crucial for your security.

Step 3: Remove the presser feet

Use a screw driver to open up the parts of sewing machine to make them visible to lubricate them easily.

Step 4: Clean the Machine

Remove any lint, dust, or debris that may be on your sewing machine before you oil it. To clean the machine, use cotton swabs or a soft cloth or a soft brush. Make careful you feed the dogs and clean the area surrounding the needles and bobbin case.

Step 5: Locate the Oil Points

Finding the oil spots on your sewing machine is the next step. The places where you need to apply oil are these. Find the oil points on your sewing machine by consulting the manual. The hook race, feed dogs, and needle bar are frequently oiled points.

Step 6: Apply Oil

It’s time to apply oil once you’ve found the oil locations. Every oil point should get a tiny drop of oil. Avoid going overboard since too much oil might draw in dirt and debris and jam the machine. Moreover, be sure to use sewing machine oil because other kinds of oil can harm the device.

Step 7: Run the Machine

It’s time to start the machine after you’ve oiled the oil points. Start the machine, then let it run slowly for a few minutes. As a result, the oil will be distributed more uniformly all through the machine.

Step 8: Wipe off Excess Oil

Once you have run the machine for a few minutes, use a soft cloth or cotton swabs to wipe off any excess oil.

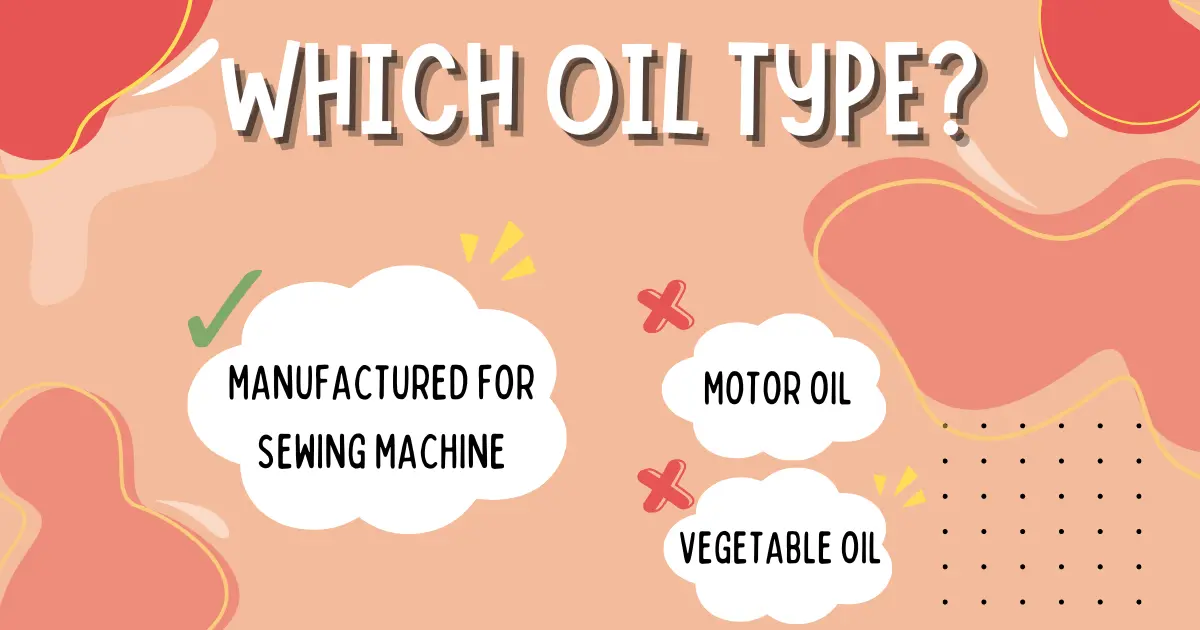

Which oil type to use to in a sewing machine?

The appropriate kind of oil must be used while maintaining and oiling a sewing machine. To lubricate the machine’s moving parts without harming them, sewing machine oil is particularly manufactured for use in sewing machines.

Other oils, such motor oil or vegetable oil, should not be used as they can damage the machine and muck up the workings. Most sewing supply stores and online retailers have clear, odorless sewing machine oil.

Verify that the oil you buy is intended particularly for use in sewing machines by reading the label. Moreover, make sure to lubricate your specific sewing machine according to the manufacturer’s directions.

Read more: Best Sewing Tables

Where to oil a sewing machine?

It’s important to know where to oil sewing machine for optimum maintenance of a sewing machine. Before you begin, make sure to consult your sewing machine’s guide because the locations where you should oil your machine may vary based on its make and model.

Generally speaking, oil should be added to all sewing machine moving parts that come into contact with other parts. The hook race, feed dogs, and needle bar are a few areas that frequently need oiling.

The bobbin rests in the hook race, which is frequently found beneath the machine’s needle plate. After removing the bobbin case, add a drop of oil to the hook race. Below the needle plate are the feed dogs, a toothed gear that aids in advancing cloth through the machine. Each feed dog should receive a drop of oil.

The mechanism that secures the needle is called the needle bar, and it is situated above the machine’s needle plate. While being careful not to get any oil on the needle itself, apply a drop of oil to the needle bar.

Run the machine for a few minutes after adding oil to these spots to help the oil spread evenly. Then, use a cotton swab or lint-free cloth to remove any extra oil.

Read more: How to sew a t-shirt

Conclusion- How to oil the sewing machine

In conclusion, oiling a sewing machine is an important step in maintaining its longevity and ensuring that it continues to function properly. By properly oiling your machine on a regular basis, you can help extend its lifespan and ensure that it continues to produce high-quality stitches for years to come.

FAQ